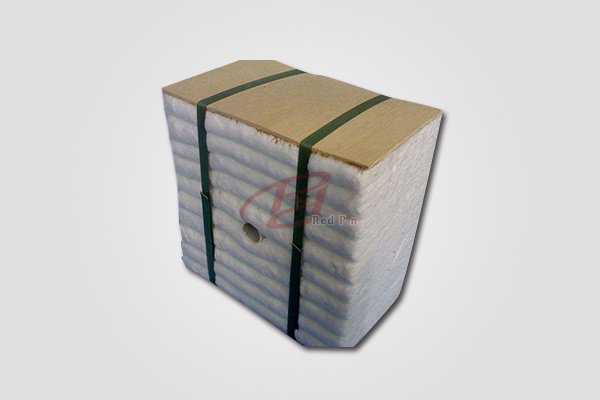

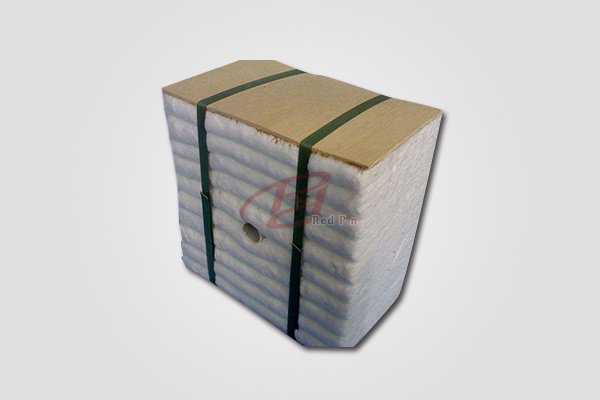

Ceramic Fiber Module

Ceramic Fiber Module is made of high quality spun fiber needle blanket, which is folded and compressed to certain structure and sizes. It is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. During the processing, a certain compression ratio must be kept to ensure that the modules can expand to all directions and can crowd into a seamless whole body when they are installed in the furnace walls.

|

Thickness (mm) |

6-50 |

|

Typical Dimensions (mm) |

600×300×300, 300×300 × 300 |

|

Density ( kg/m3) |

180-240 |

|

Working Temperature |

1000-1430℃ |

It features Fast and easy installation, Lower heat storage and fuel costs and so on.

Product Benefits:

Low heat conduction rate

Low heat storage & energy saving

Fast and easy installation

Resistance to heat shock

Good chemical stability

Applications:

It is mainly used for furnace linings of all kinds of industrial furnaces and heating devices in metallurgy, machinery, building materials, petro-chemical & nonferrous metals.